process

Introduction to Neotech and the Goods Production Process

This is the production process of Neotech’s goods,

a research company specializing in foot health

Production Process

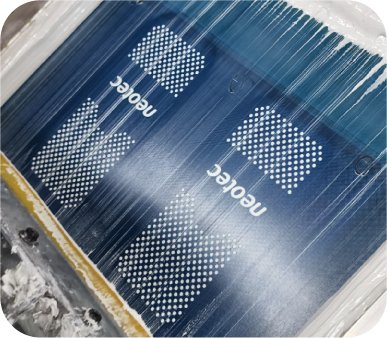

Non slip socks

non slip socks

Anti-slip socks are highly recommended for those who tend to slip indoors. Neotech's anti-slip socks can be used for 4 seasons and are practical. In addition, the soles of the feet are dotted with durable materials to support safe walking. It is recommended for elderly people with mobility difficulties and people with disabilities who have no strength in their legs or are uncomfortable due to a lack of balance their bodies.

No-pressure foot care socks

No-pressure foot care socks

We develop and manufacture functional socks through research and development over the years. Pressure-free foot care socks are products that have been patented (No. 10-2018-0103886) and have been developed with minimal pressure bands not to tighten the ankles. It is a diagonal band that can only apply minimal pressure, reducing the pressure on the ankle and preventing it from falling. Highly recommended for diabetics who need to take care of their feet.

Production process

step

01

Material ordering and separate dyeing

Yarn ordering (cotton coma 30 thread yarn ordering) and rubber yarn ordering and separate dyeing (rubber 30 & nylon 70 & 90 rubber nylon) are carried out.

step

02

Yarn dyeing and combination dyeing of antimicrobial ALPHARIUM

Yarn dye (cotton 30 comasasu) and proceed to foreground.

Combination dyeing of antimicrobial ALPHARIUM is done in the dyeing process.

(ALPHARIUM: antibacterial, odor removal, blood circulation)

step

03

Warping and weaving

Proceed with the cone work process so that the dyed yarn can be weaved.

and 168 Double Cylinder, 132 file, 200 Single Cylinder the weaving process.

neotec

step

04

A hand sewing process

The front part of the socks get sewn.

step

05

Work of anti-slip dot and raw material mixture with ALPHARIUM and dot

The dots on the soles of the feet get processed and the raw materials of the ALPHARIUM and the dots.

step

06

Processing

Iron on the socks with steam.

step

07

I-pin, packaging and shipping

Put label stickers.

TOP